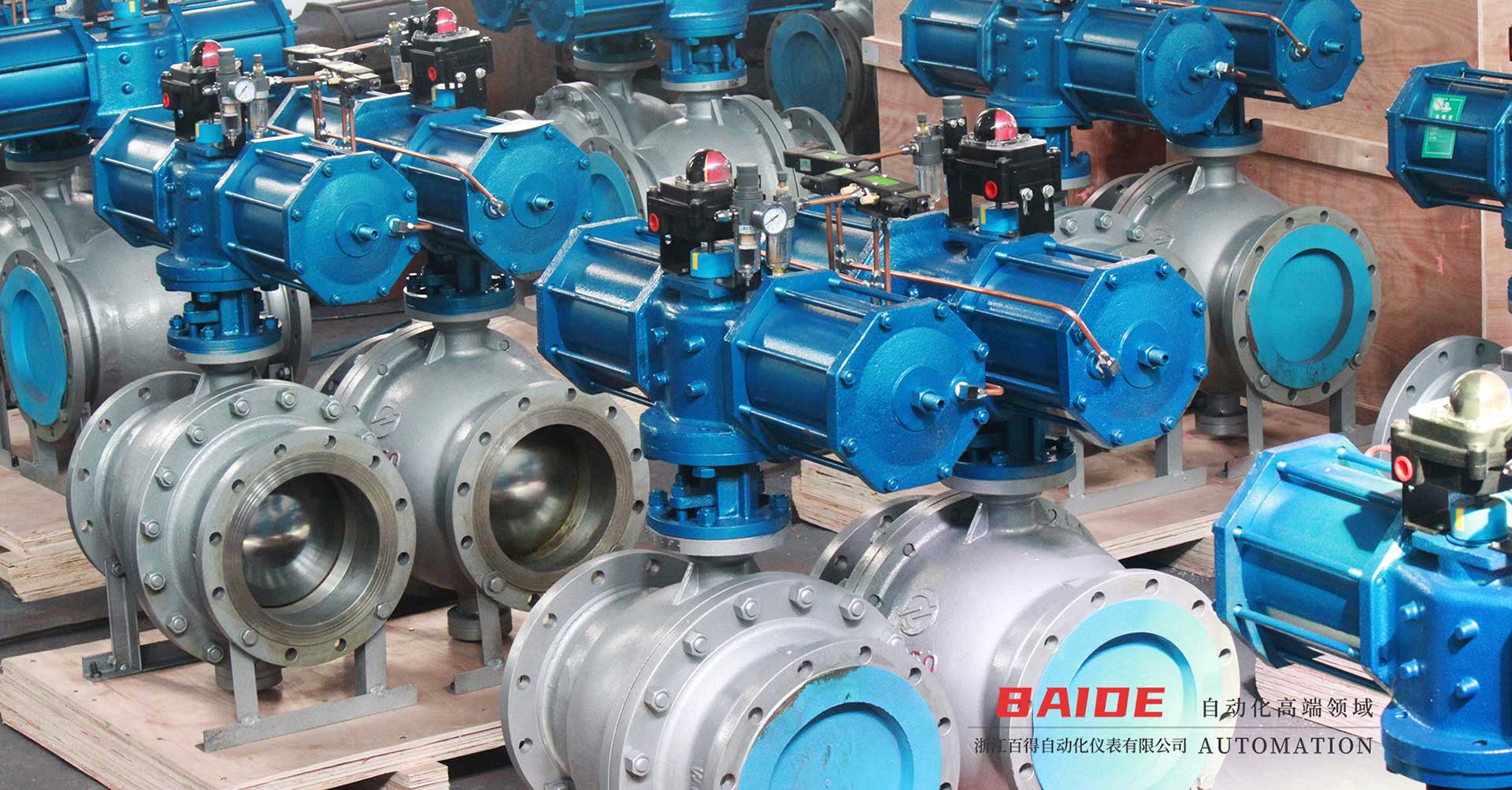

Explosion-proof pneumatic ball valves Q641FB, Q671FB adopts AT, GT, AW, G series pneumatic actuators configuration with explosion-proof solenoid reversing valve, explosion-proof limit switch, explosion-proof positioner and other explosion-proof components + floating ball valve or other structure ball valve composition with reliable explosion-proof performance. Pneumatic explosion-proof ball valves are widely used in chemical, petroleum, light textile, electric power, refrigeration, aviation, aerospace and other industrial fields with high requirements for explosion-proof.

Nominal diameter: DN50-500mm

Connection type: Flange

Cylinder configuration: AT series、AWseries

Cylinder form: Double acting, single acting (spring reset)

Control direction: two-position cut-off (switch type), regulating type, three-stage (open degree optional)

Nominal pressure: 16、25、40bar (please specify when ordering higer pressure)

Air source pressure: 4~7bar

Medium temperature: MF3:-40~220℃ MF4:-40~300℃ MF5:-40~425℃ MF6:-60~425℃

Ambient temperature Standard: -20~80℃

Valve body material: Carbon steel、Stainless steel

Seal material: PTFE ( MF3 ), para-polystyrene ( MF4 ), metal hard seal ( MF5 ), hard alloy ( MF6 )

| Pneumatic Explosion-proof Ball Valve main external and connection size 1.6-4.0MPa | ||||||||||||

| Nominal Diameter DN | L | D | D1 | z-¢d | L | D | D1 | z-¢d | L | D | D1 | z-¢d |

| 1.6MPa | 2.5MPa | 4.0MPa | ||||||||||

| 15 | 203 | 160 | 125 | 4-¢18 | 216 | 160 | 125 | 4-¢18 | 216 | 160 | 125 | 4-¢18 |

| 65 | 222 | 180 | 145 | 4-¢18 | 241 | 180 | 145 | 8-¢18 | 241 | 180 | 145 | 8-¢18 |

| 80 | 241 | 195 | 160 | 8-¢18 | 283 | 195 | 160 | 8-¢18 | 283 | 195 | 160 | 8-¢18 |

| 100 | 305 | 215 | 180 | 8-¢18 | 305 | 230 | 190 | 8-¢23 | 305 | 230 | 190 | 8-¢23 |

| 125 | 356 | 245 | 210 | 8-¢18 | 381 | 270 | 220 | 8-¢25 | 381 | 270 | 220 | 8-¢25 |

| 150 | 394 | 280 | 240 | 8-¢23 | 403 | 300 | 250 | 8-¢25 | 403 | 300 | 250 | 8-¢25 |

| 200 | 457 | 335 | 295 | 12-¢23 | 502 | 360 | 310 | 12-¢25 | 502 | 375 | 320 | 12-¢30 |

| 250 | 533 | 405 | 355 | 12-¢25 | 586 | 425 | 370 | 12-¢30 | ||||

| 300 | 610 | 460 | 410 | 12-¢25 | 658 | 285 | 430 | 16-¢30 | ||||

| 350 | 686 | 520 | 470 | 16-¢25 | 762 | 550 | 490 | 16-¢34 | ||||

| 400 | 762 | 580 | 525 | 16-¢30 | 838 | 610 | 550 | 16-¢34 | ||||

| 450 | 864 | 640 | 585 | 20-¢30 | 914 | 660 | 600 | 20-¢34 | ||||

| 500 | 914 | 705 | 650 | 20-¢34 | 991 | 730 | 660 | 20-¢41 | ||||